Product Description

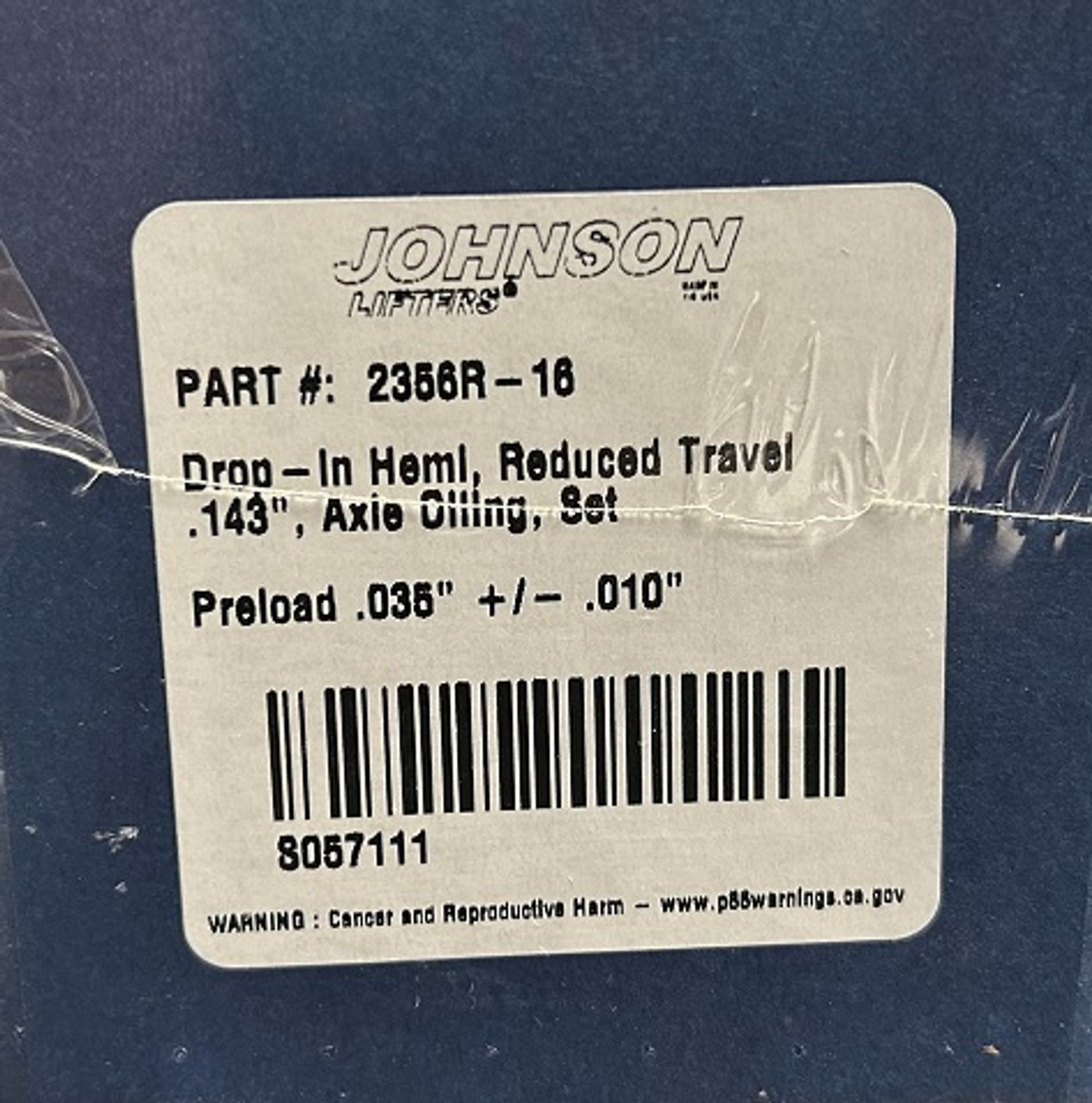

Johnson 2356R-16 Drop-In Lifters with Axle Oiling for Gen 3 Hemi

Fits 2003-newer Dodge Chrysler Jeep Hemi Engines 5.7L 6.1L 6.2L 6.4L

Johnson's 2356 drop-in lifters are the most durable direct-fit lifters available for your high-RPM Gen III Hemi build. These non-MDS reduced travel hydraulic roller lifters are designed to use factory style lifter trays (trays not included). These lifters will typically require a longer pushrod (please measure for proper pushrod length when installing). MDS system must be physically deleted and programmed out of the PCM when running Johnson lifters.

- Reduced Travel Hydraulic-Roller Lifters

- Axle-oiling provides extra durability for high RPM, high spring pressure applications

- .143" Total Plunger Travel

- .035" Recommended Pre-Load +/-.010"

- Cold forged steel body heat treated for exceptional wear resistance.

- Precision ground needle roller bearing with high chromium steel axle for long life and low friction.

- Cold forged extra long piston, precision ground and fitted for controlled leak down and pump up.

- High flow disc style quick reacting check valve for better reaction at higher RPM.

- Precision oil metering assuring proper oiling to the rocker arms without sacrificing oil pressure.

- Set of 16 Lifters

- Made in USA!

Applications include (5.7L, 6.1L, 6.2L and 6.4L V8 models only):

- CHRYSLER 300 2005-2023

- DODGE CHALLENGER 2008-2023

- DODGE CHARGER 2006-2023

- DODGE DURANGO 2004-2023

- DODGE MAGNUM 2005-2008

- DODGE RAM 1500 PICKUP 2003-2010

- DODGE RAM 2500 PICKUP 2003-2010

- DODGE RAM 3500 PICKUP 2003-2009

- JEEP GRAND CHEROKEE 2005-2023

- RAM 1500 2011-2023

- RAM 2500 2011-2023

- RAM 3500 2011-2023

Recommended Lifter Installation:

1. Inspect the lifters for any signs of damage to the lifter body or wheel.

2. Verify the rollers spin without any binding.

3. Wipe down the lifter body with a lint free rag.

4. Coat the outside of the lifter with engine oil (not recommended to soak)

5. Debris entering a lifter is the main cause of failure. Clean the top end of the engine to ensure no foreign debris can enter the lifters upon startup.

6. Inspect the Rocker Arms, Pushrods Ends, and Valve Tips for excessive wear. Replace as necessary.

7. Install lifters and set the lifter preload to the recommended specifications.

8. Change oil/filter after 50 miles to remove any debris that may have been missed during assembly.